Product categories

News and information

Qingdao Yifei Plastic Welding Equipment Co., Ltd..

Postal Code: 266300

Tel:086-532-86226666/86228888/86226668

Fax: 086-532-86226387

Contact: Mr. Liu

E-mail: yfwelder@gmail.com

Add: Qingdao Jiaozhou City Industrial Park Hasan(with the three-Tai high-speed exit)

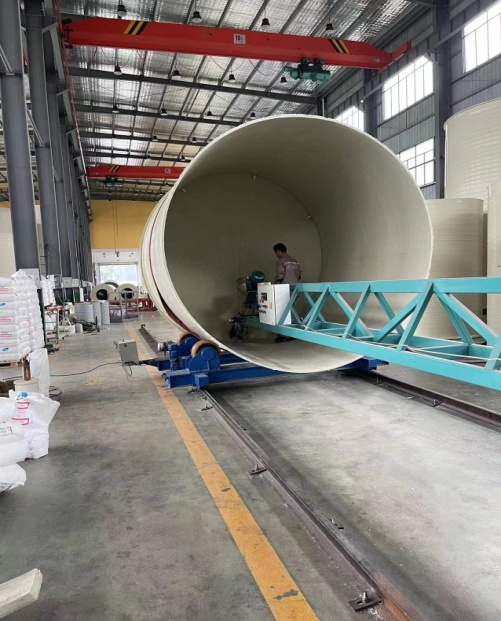

PPH (PP/HDPE) winding storage tank production line forming process adopts spiral extrusion winding technology, the main processes include tank extrusion winding, external welding, internal welding, pipe mouth installation, etc. The thickness of PPH winding tank can reach more than 60mm, its profile can be gradually changed, and the raw material is concentrated in the parts with high stress, thus significantly improving the mechanical strength and compressive capacity of the tank. The tank body of the winding tank adopts the design of no weld, which can avoid the danger of leakage. Due to the improvement of its mechanical strength and safety and reliability, it can be used in the environment of higher than atmospheric pressure, while ordinary storage tanks can only be used in the environment of atmospheric pressure. The service life of wound tank is 3-4 times that of ordinary tank, the service life of ordinary plastic tank is 3-4 years, and the service life of PPH wound tank is more than 15 years. Compared with the glass fiber reinforced plastic industry, the service life and impact resistance of ordinary glass fiber reinforced plastic tank are more than two times, and can replace stainless steel, nickel, titanium and other metal containers in a considerable range. It is an ideal new generation of chemical liquid corrosion resistant storage and transportation equipment, and cheap and fine. Products are widely used in chemical, dye, pesticide, metallurgy, rare earth, machinery, power, electronics, environmental protection, textile, brewing, food, water supply, drainage and other industries.

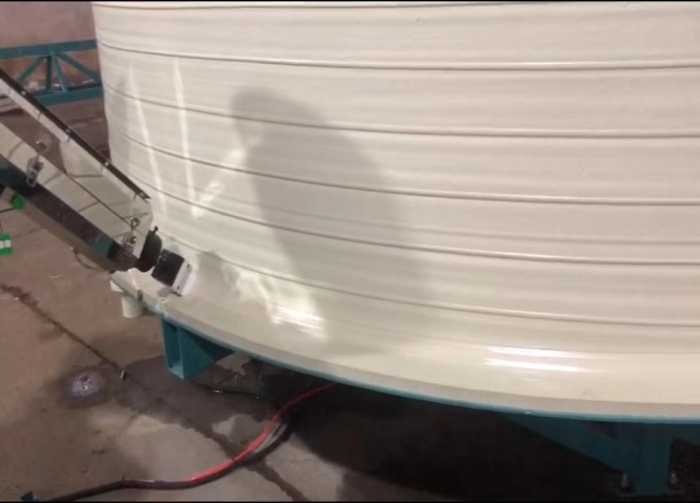

1. Extrusion and winding production of tank body: Tank body is the process of processing PPH particles into tank body by PPH spiral extrusion and winding unit. The system adopts the process of hot melting and extrusion of PPH particles and then winding the steel mold into a tank. The production efficiency is 5-8 times higher than the manual. The product integrity is good, no seams, corrosion resistance, leakage resistance is good. The product is smooth and beautiful, and the tank body is thin and thick and the price is reduced

Two, external welding production: external welding is the process of using automatic extrusion welding unit to make storage tank and bottom plate welding molding. The new PPH particle material with the same property as the tank body is hot melted in the large weld, and the tank bottom and tank body into one. Bottom welding process characteristics: ◆ The product can be designed according to the stress characteristics of the weld specifications, make it give full play to the integrity of the weld. The product integrity is good, the weld and the parent body, corrosion resistance, leakage resistance is good, ◆ can reduce the flying edge, joint smooth and beautiful ◆ in PPH particle material add ultraviolet absorber, prevent aging, Prolong the service life.

Three, internal welding production: internal welding is the use of automatic long arm extrusion welding process, is an important step in all processes. The new PPH particle material with the same property as the tank body is hot melted in the internal weld, and the tank bottom and tank body into one, the principle and process are the same as the external welding, only its equipment is different.

PPH winding storage tank is mainly used in the equipment of the following industries: (1) In the new energy industry, it is mainly used in the storage tank, transit tank, mixing tank, reaction tank, etc. required by various production processes. (2) in the environmental protection industry is mainly used for the production of waste gas treatment tower equipment. (3) in the chemical and pharmaceutical industry is mainly used in horizontal storage tank, metering tank, etc.

our Product

General Manager: Liu Peng Office: 0532-86226666

Mobile phone: 13606302802

Tel: 0532-86226666 86228888

Fax: 0532-86225678

Address: Aishan Industrial Park, Jiaozhou City, Qingdao (Wangtai Exit of Tongsan Expressway)

Mobile Scan View